This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Aftercooler Pipe, part number 3276600, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance engine components. This part is significant in the context of heavy-duty truck engines as it plays a role in enhancing engine efficiency and performance.

Basic Concepts of Aftercooler Pipes

An aftercooler pipe is a component within the engine system that facilitates the cooling of compressed air before it enters the engine’s combustion chamber. This cooling process increases the density of the air, allowing for more efficient combustion. The aftercooler pipe contributes to the overall performance and efficiency of the engine by ensuring that the air entering the combustion chamber is at an optimal temperature and pressure 1.

Role of the Aftercooler Pipe in Truck Operation

This Cummins part is integral to the operation of a truck. It interacts with other engine components such as the turbocharger and intercooler, playing a role in the air intake system by directing cooled air to the engine. This interaction enhances engine performance by ensuring that the engine receives air at the correct temperature and pressure, which is crucial for efficient combustion and power output.

Key Features of the Aftercooler Pipe 3276600

The Aftercooler Pipe 3276600 is designed with specific features that enhance its function. It is constructed from durable materials that can withstand the high pressures and temperatures within the engine system. The pipe is engineered to provide a secure and efficient pathway for the cooled air, ensuring that it reaches the engine in optimal condition. Additionally, the design of the pipe includes features that facilitate easy installation and integration within the engine system.

Benefits of Using the Aftercooler Pipe 3276600

The use of this part provides several advantages. It contributes to improved engine efficiency by ensuring that the air entering the combustion chamber is at the optimal temperature and pressure. This results in more efficient combustion, which can lead to enhanced fuel efficiency and reduced emissions. The durable construction of the pipe also ensures that it can withstand the demanding conditions within the engine system, providing long-lasting performance 2.

Installation and Integration

Proper installation of the Aftercooler Pipe 3276600 is crucial to ensure its optimal function within the engine system. It should be installed according to the manufacturer’s guidelines, ensuring that it is securely connected to other components within the air intake system. Any prerequisites or special considerations should be adhered to during the installation process to ensure the longevity and performance of the pipe.

Maintenance and Troubleshooting

Regular maintenance of the Aftercooler Pipe 3276600 is important to ensure its longevity and optimal performance. This may include periodic inspections for any signs of wear or damage, and cleaning to remove any debris that may have accumulated within the pipe. Common issues that may arise include leaks or blockages, which can be addressed through proper troubleshooting steps such as checking connections and clearing obstructions.

Performance Impact

The Aftercooler Pipe 3276600 has a notable impact on the overall performance of the truck. By ensuring that the air entering the engine is at the optimal temperature and pressure, it contributes to enhanced fuel efficiency, increased power output, and reduced emission levels. This results in a more efficient and environmentally friendly operation of the truck.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, particularly known for its high-performance engine components. The company has a rich history of innovation and quality, producing a wide range of products that are trusted by professionals in the industry. Cummins’ reputation is built on its commitment to quality, reliability, and performance, making it a preferred choice for heavy-duty truck components.

Cummins Aftercooler Pipe (Part 3276600) Compatibility

The Cummins Aftercooler Pipe, identified by part number 3276600, is a critical component in the cooling system of various Cummins engines. This part is designed to facilitate the flow of air from the turbocharger to the aftercooler, ensuring efficient heat exchange and optimal engine performance.

L10 MECHANICAL

The L10 MECHANICAL engine is one of the engines that can utilize the Cummins Aftercooler Pipe (3276600). This engine is known for its robust design and reliability, often used in heavy-duty applications. The aftercooler pipe in this engine setup plays a vital role in maintaining the air temperature entering the engine, which is crucial for performance and longevity.

Grouping of Engines

The Cummins Aftercooler Pipe (3276600) is compatible with several other engines within the Cummins lineup, particularly those that feature similar cooling systems and require efficient air management. These engines often share common design principles and performance characteristics, making the aftercooler pipe a versatile component across multiple models.

By ensuring a seamless fit and function, the Cummins Aftercooler Pipe (3276600) contributes to the overall efficiency and reliability of the engine systems it is integrated into.

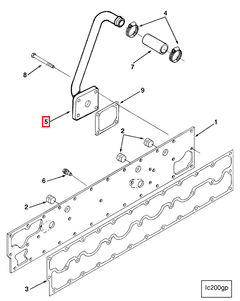

Role of Part 3276600 Aftercooler Pipe in Engine Systems

The Part 3276600 Aftercooler Pipe is an integral component in the efficient operation of engine systems, particularly in those utilizing aftercoolers and oil coolers. This pipe facilitates the connection between various components, ensuring smooth and effective fluid transfer.

Integration with Plumbing Systems

In engine systems, the aftercooler pipe is often connected to the plumbing network. This connection allows for the regulated flow of fluids, such as coolant or lubrication oil, between different parts of the engine. The pipe’s role in the plumbing system is to maintain consistent fluid levels and pressures, which are essential for the engine’s optimal performance.

Interaction with Aftercooler Water Systems

The aftercooler pipe is designed to work in conjunction with aftercooler water systems. Aftercoolers are used to cool the compressed air from the turbocharger before it enters the engine’s combustion chamber. The aftercooler pipe ensures that the water used in this cooling process is efficiently circulated. This helps in maintaining the desired temperature of the air, which in turn enhances the engine’s efficiency and power output.

Connection to Oil Cooler Water Systems

In systems where oil coolers are employed, the aftercooler pipe plays a significant role. Oil coolers are used to regulate the temperature of the engine oil, preventing it from overheating. The aftercooler pipe facilitates the connection between the oil cooler and other parts of the engine, allowing for the effective circulation of cooling water. This ensures that the engine oil remains at an optimal temperature, which is vital for the longevity and performance of the engine.

Overall Functionality

The Part 3276600 Aftercooler Pipe is a key element in the engine’s cooling and lubrication systems. By ensuring the efficient transfer of fluids between components like the aftercooler and oil cooler, it contributes to the engine’s overall reliability and performance. Its integration into the plumbing, aftercooler water, and oil cooler water systems underscores its importance in maintaining the engine’s operational integrity.

Conclusion

The Cummins Aftercooler Pipe, part number 3276600, is a critical component in the efficient operation of heavy-duty truck engines. Its role in cooling compressed air before it enters the combustion chamber enhances engine efficiency and performance. The durable construction and specific design features of this part ensure long-lasting performance and easy integration within the engine system. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, contributing to improved fuel efficiency, increased power output, and reduced emissions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.