This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 214836 Aftercooler Core is a component designed to enhance the performance and efficiency of heavy-duty trucks. It plays a role in the cooling process post-turbocharging, contributing to the overall effectiveness of the engine system 1.

Basic Concepts of Aftercooler Cores

An aftercooler core is a heat exchanger that cools the compressed air from the turbocharger before it enters the engine. This cooling process increases the air density, allowing more oxygen to enter the combustion chamber, which enhances engine performance and efficiency. The aftercooler core is integral to maintaining optimal engine operation by ensuring that the air entering the engine is at the correct temperature and pressure 2.

Purpose of the Cummins 214836 Aftercooler Core

The Cummins 214836 Aftercooler Core is specifically designed to cool the compressed air from the turbocharger in heavy-duty trucks. By reducing the temperature of the air, it increases the air density, which in turn improves combustion efficiency and power output. This component is vital for maintaining the engine’s performance under various operating conditions 3.

Key Features

The Cummins 214836 Aftercooler Core is characterized by its robust design and high-quality materials. It features a compact yet efficient structure that maximizes heat exchange. The core is constructed from durable materials to withstand the harsh conditions of heavy-duty truck operations. Additionally, it includes advanced fin technology to enhance cooling efficiency and ensure long-term reliability.

Benefits of Using the Cummins 214836 Aftercooler Core

Incorporating the Cummins 214836 Aftercooler Core into a truck’s engine system offers several advantages. It improves engine efficiency by ensuring that the air entering the combustion chamber is at the optimal temperature. This results in better fuel economy and increased power output. Furthermore, the enhanced cooling process contributes to the longevity of the engine by reducing thermal stress on components.

Installation and Integration

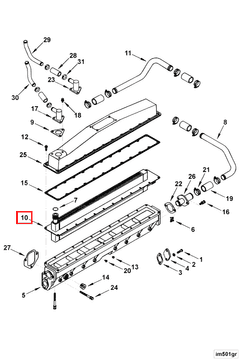

Proper installation of the Cummins 214836 Aftercooler Core is crucial for ensuring its effectiveness. It should be integrated into the engine system according to the manufacturer’s guidelines to avoid any potential issues. Best practices include ensuring a secure fit, proper alignment, and correct connection of all hoses and fittings. Attention to detail during installation will help maintain the core’s performance and durability.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 214836 Aftercooler Core is essential for optimal performance. This includes routine inspections to check for any signs of damage or wear. Cleaning the core to remove any debris or buildup is also important. Troubleshooting common issues such as reduced cooling efficiency or leaks can often be addressed by inspecting connections and ensuring the core is free from obstructions.

Performance Enhancements

The Cummins 214836 Aftercooler Core contributes to overall truck performance in several ways. By improving the efficiency of the air cooling process, it enhances fuel efficiency and increases power output. Additionally, the improved air quality entering the engine can lead to reduced emissions, making the truck more environmentally friendly.

Compatibility and Applications

The Cummins 214836 Aftercooler Core is designed to be compatible with a range of heavy-duty trucks and engine models. It is suitable for use in various commercial trucking scenarios, including long-haul transportation, construction, and logistics. Its versatile design ensures it can meet the demands of different applications, providing reliable performance across diverse operating conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial trucking industry for producing high-quality, reliable components. The company’s extensive product range includes engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. The Cummins 214836 Aftercooler Core is a testament to the company’s commitment to innovation and excellence in the field of engine cooling technology.

Cummins Aftercooler Core Part 214836 Compatibility

The Cummins Aftercooler Core part number 214836 is designed to fit seamlessly with several engine models, ensuring optimal performance and efficiency. This part is engineered to integrate with the following engines:

N14 G Engine

The N14 G engine, known for its robust design and high performance, is compatible with the Cummins Aftercooler Core part 214836. This part enhances the engine’s cooling system by providing an efficient aftercooling process, which helps maintain optimal operating temperatures and improves overall engine efficiency.

V28 Engine

Similarly, the V28 engine benefits from the integration of the Cummins Aftercooler Core part 214836. This part ensures that the engine’s cooling system operates at peak efficiency, contributing to better performance and longevity of the engine. The V28 engine, like the N14 G, relies on the aftercooler core to manage heat effectively and maintain stable operating conditions.

Compatibility Summary

The Cummins Aftercooler Core part 214836 is specifically designed to fit both the N14 G and V28 engines. This compatibility ensures that users of these engines can rely on a high-quality aftercooling solution that enhances engine performance and efficiency. The seamless integration of this part with both engine models underscores Cummins’ commitment to providing reliable and effective components for their engines.

Role of Part 214836 Aftercooler Core in Engine Systems

The Part 214836 Aftercooler Core is an integral component in various engine systems, designed to enhance performance and efficiency. It is specifically engineered to work in conjunction with several key components to optimize the cooling process of compressed air from the turbocharger arrangement.

Integration with Aftercooler Systems

The Aftercooler Core is a fundamental part of the aftercooler, which is responsible for reducing the temperature of the air after it has been compressed by the turbocharger. This cooling process increases the air density, allowing more air to enter the combustion chamber and thus improving engine efficiency and power output.

Compatibility with Conversion Kits

When used with an Aftercooler Conversion Kit or Aftercooler Cooler Conversion Kit, the Aftercooler Core facilitates the transformation of an engine system to incorporate aftercooling. This integration ensures that the compressed air is effectively cooled before it enters the engine, which is essential for maintaining optimal engine performance under various operating conditions.

Interaction with Air Intake and Intercooler Components

The Aftercooler Core works seamlessly with the Air Intake Intercooler and Air Intercooler to further cool the air after it has passed through the turbocharger. This multi-stage cooling process is vital for high-performance engines, where even minor improvements in air temperature can lead to significant gains in power and efficiency.

Role in the Intake Manifold System

In conjunction with the Intake Manifold and Intake MFLD, the Aftercooler Core ensures that the cooled air is evenly distributed to all cylinders. This uniform distribution is key to achieving balanced combustion across the engine, which is critical for smooth operation and longevity.

Mounting and Assembly Considerations

The Aftercooler Core is designed to be compatible with various mounting configurations, including Air Intercooler Mounting, Air Mounting Intercooler, and Intercooler Air Mounting. These mounting systems secure the Aftercooler Core in place, ensuring it remains stable and efficient during engine operation.

Enhanced Performance with Intercooler Kits

When integrated into an Intercooler Kit, the Aftercooler Core contributes to a comprehensive cooling solution. This setup is particularly beneficial for turbocharged engines, where the high temperatures of compressed air can lead to decreased performance and increased wear.

Noise Reduction and Turbocharger Efficiency

The Aftercooler Core also plays a role in reducing noise from the Intake Manifold, contributing to a quieter engine operation. Additionally, by ensuring that the air entering the turbocharger is at an optimal temperature, the Aftercooler Core helps maintain the efficiency and reliability of the turbocharger arrangement.

Conclusion

In summary, the Part 214836 Aftercooler Core is a versatile and essential component that enhances the performance and efficiency of engine systems through effective air cooling. Its compatibility with a wide range of components ensures that it can be integrated into various engine configurations to achieve the best possible results.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.