This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

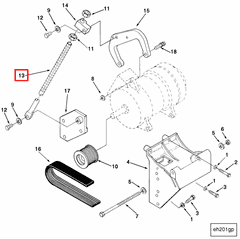

The Adjusting Link 3883414 is a component produced by Cummins, designed specifically for use in heavy-duty trucks. This part plays a role in the suspension system, contributing to the vehicle’s overall performance and stability. Understanding its function and significance is important for maintaining the efficiency and safety of heavy-duty trucks 1.

Purpose and Function

The Adjusting Link 3883414 is integral to the truck’s suspension system. It allows for precise adjustments to the suspension, which can affect the vehicle’s ride height, load distribution, and overall handling. By enabling fine-tuning of these parameters, the link contributes to improved performance and stability, ensuring that the truck operates efficiently under various conditions 2.

Key Features

The Adjusting Link 3883414 is constructed from high-quality materials, ensuring durability and reliability. Its design includes specific dimensions tailored to fit within the suspension system of compatible trucks. Unique characteristics such as corrosion-resistant coatings and robust construction enhance its functionality, allowing it to withstand the rigors of heavy-duty use 3.

Benefits

Incorporating the Adjusting Link 3883414 into a truck’s suspension system offers several advantages. It allows for better load handling by enabling precise adjustments to the suspension, which can improve the truck’s ability to carry heavy loads without compromising stability. Additionally, it enhances ride comfort by allowing for fine-tuning of the suspension settings, which can reduce the impact of road irregularities on the vehicle and its cargo. The link’s durable construction ensures it can withstand the demands of heavy-duty use, contributing to the truck’s longevity 4.

Installation and Usage

Proper installation of the Adjusting Link 3883414 is important for ensuring its correct operation. The process involves several steps, including preparing the suspension system, fitting the link into place, and making necessary adjustments. Tools required may include wrenches, sockets, and possibly a torque wrench to ensure proper tightening. It is important to follow the manufacturer’s guidelines to ensure the link is installed correctly and operates as intended 1.

Maintenance and Troubleshooting

Regular maintenance of the Adjusting Link 3883414 is important for ensuring its continued performance. This includes periodic inspections for signs of wear, corrosion, or damage. Common issues to look out for include loose fittings, worn components, and signs of corrosion. Recommended troubleshooting steps may involve tightening loose components, replacing worn parts, or applying protective coatings to prevent corrosion 2.

Safety Considerations

When working with the Adjusting Link 3883414, it is important to follow safety guidelines to ensure safe operation. This includes using proper tools and equipment, following manufacturer instructions for installation and maintenance, and ensuring the vehicle is securely supported when performing adjustments or repairs. Proper handling and maintenance of the link are important for the safe and efficient operation of the truck 3.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its wide range of products including engines, powertrains, and components. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance parts that meet the demands of heavy-duty applications. The company’s commitment to excellence is reflected in its products, including the Adjusting Link 3883414 4.

Conclusion

The Adjusting Link 3883414 by Cummins is a vital component in the suspension system of heavy-duty trucks, offering precise adjustments that enhance performance, stability, and load handling. Its durable construction and corrosion-resistant features ensure longevity and reliability under demanding conditions. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ ↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ ↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ ↩ -

Cummins Inc. (n.d.). Owners Manual for B6.7 CM2350 B157C. Bulletin Number 5579682.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.