This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3284346 Adjusting Link End is a component designed for use in commercial trucks. It serves a specific function within the truck’s suspension system, contributing to the overall performance and stability of the vehicle. Understanding its purpose and role can provide insight into how it enhances the operation of commercial trucks.

Basic Concepts of Adjusting Link End

An adjusting link end is a part of the suspension system that allows for the adjustment of the suspension’s geometry. This component plays a role in maintaining the correct alignment and height of the truck’s suspension, which is vital for ensuring optimal performance, stability, and ride comfort. By enabling fine-tuning of the suspension, the adjusting link end contributes to the truck’s ability to handle various loads and road conditions effectively 1.

Purpose and Role in Truck Operation

The Cummins 3284346 Adjusting Link End is specifically designed to integrate into the truck’s suspension system. Its purpose is to provide a means of adjusting the suspension’s components to achieve the desired ride height, alignment, and stability. This adjustment capability is crucial for accommodating different load conditions and ensuring that the truck maintains optimal performance and safety standards. By enhancing the suspension’s adaptability, the adjusting link end plays a role in improving the truck’s handling, load-carrying capacity, and overall ride comfort 2.

Key Features

The Cummins 3284346 Adjusting Link End is characterized by several key features that distinguish it from other similar parts. It is constructed from durable materials to withstand the rigors of commercial truck operation. The design includes specific elements that allow for precise adjustments, ensuring that the suspension system can be fine-tuned to meet the truck’s operational requirements. Additionally, the adjusting link end may feature unique characteristics such as corrosion-resistant coatings or enhanced strength properties, which contribute to its reliability and longevity 3.

Benefits

The Cummins 3284346 Adjusting Link End offers several benefits that enhance the performance and efficiency of commercial trucks. Its durable construction and precise adjustment capabilities contribute to improved suspension performance, which can lead to better handling, increased load-carrying capacity, and enhanced ride comfort. Over time, the reliable design of the adjusting link end can result in potential cost savings by reducing the need for frequent replacements or repairs 4.

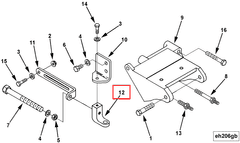

Installation Process

Installing the Cummins 3284346 Adjusting Link End requires careful attention to ensure proper fitting and functionality. The process involves several steps, including preparing the suspension system for the new component, using the appropriate tools to make any necessary adjustments, and securing the adjusting link end in place. It is important to follow the manufacturer’s guidelines to ensure that the installation is performed correctly, which will help maintain the suspension system’s performance and safety.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 3284346 Adjusting Link End can include misalignment, wear, or damage. Troubleshooting these problems involves inspecting the component for signs of wear or damage, checking the suspension’s alignment, and making any necessary adjustments or replacements. Addressing these issues promptly can help maintain the suspension system’s performance and prevent more significant problems from developing.

Maintenance Tips

Regular maintenance of the Cummins 3284346 Adjusting Link End is important for prolonging its life and ensuring optimal performance. This includes inspecting the component for signs of wear or damage, cleaning it to remove any dirt or debris, and making any necessary adjustments to maintain the suspension’s alignment. Following a regular maintenance schedule can help identify potential issues early, allowing for timely repairs or replacements and ensuring the truck’s suspension system remains in top condition.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a history of providing reliable and high-performance products, Cummins has built a reputation for excellence. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial trucks. Cummins’ dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Compatibility with Cummins Engines

The Adjusting Link End part 3284346, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part plays a role in the engine’s operation by ensuring precise adjustments and maintaining the integrity of the engine’s mechanical linkages.

ISM CM570 and ISM CM570/870

For the ISM CM570 and ISM CM570/870 engines, the Adjusting Link End part 3284346 is integral to the engine’s valve train system. This part ensures that the valve linkages are properly aligned and adjusted, which is essential for maintaining optimal engine performance and longevity. The ISM CM570/870 variant, being a higher displacement version, requires precise adjustments to handle increased power output and torque, making this part particularly vital for its operation.

M11 CELECT PLUS

The M11 CELECT PLUS engine also benefits from the Adjusting Link End part 3284346. This engine, known for its robust design and advanced features, relies on this part to maintain the precise alignment of its valve linkages. The M11 CELECT PLUS is equipped with Cummins’ CELECT technology, which enhances fuel efficiency and reduces emissions. The Adjusting Link End part ensures that the mechanical components work in harmony with the electronic controls, contributing to the engine’s overall efficiency and performance.

Role in Engine Systems

Part 3284346, the Adjusting Link End, is integral to the efficient operation of various engine components. Its primary function is to facilitate precise adjustments and maintain optimal alignment between interconnected parts. This ensures smooth operation and longevity of the engine system.

Interaction with Mounting Components

The Adjusting Link End plays a significant role in the mounting system of an engine. It allows for fine-tuning the positioning of engine mounts, which are essential for absorbing vibrations and ensuring the engine remains securely in place. Proper alignment facilitated by the Adjusting Link End reduces wear on mounting brackets and enhances the overall stability of the engine within the vehicle’s chassis.

Contribution to Alternator Functionality

In the context of the alternator, the Adjusting Link End is used to adjust the tension of the serpentine belt. This is vital for the alternator to function correctly, as the belt drives the alternator pulley. Adequate tension ensures efficient power generation and charging of the battery, preventing issues such as slipping or excessive wear on the belt. The Adjusting Link End allows mechanics to make necessary adjustments to maintain the correct belt tension, thereby ensuring the alternator operates within its optimal range.

Conclusion

The Cummins 3284346 Adjusting Link End is a critical component for both the suspension system of commercial trucks and the valve train systems of Cummins engines. Its role in facilitating precise adjustments and maintaining optimal alignment is essential for the efficient operation and longevity of these systems. Regular maintenance and proper installation are key to ensuring the Adjusting Link End performs its function effectively, contributing to the overall performance and reliability of the vehicle.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.