This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Pressure Sensing Line 3284259 is a component designed by Cummins for use in commercial trucks. This part is integral to the truck’s operation, contributing to the overall efficiency and reliability of the vehicle. Its role is to monitor and transmit pressure data within the truck’s system, ensuring that various components operate within their optimal parameters 2.

Basic Concepts of Pressure Sensing Lines

A pressure sensing line is a conduit that facilitates the measurement and transmission of pressure data from one part of a system to another. In the context of a truck, it plays a role in the system by allowing sensors to detect pressure changes in critical areas such as the fuel system, hydraulic systems, or engine compartments. This data is then used by the truck’s electronic control unit (ECU) to make adjustments that maintain optimal performance and prevent potential issues 1.

Purpose of the 3284259 Pressure Sensing Line

The 3284259 Pressure Sensing Line is specifically designed to integrate with Cummins engines and related systems. It serves to relay accurate pressure readings from the engine to the ECU, which uses this information to regulate fuel injection, manage engine load, and ensure that the engine operates efficiently under varying conditions. This line is part of a broader system that includes sensors, the ECU, and actuators, all working together to maintain engine health and performance.

Key Features

The 3284259 Pressure Sensing Line is constructed from durable materials that can withstand the high pressures and temperatures found within a truck’s engine compartment. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the line may feature unique characteristics such as reinforced sections to handle particularly high-pressure areas or specialized coatings to resist corrosion and wear.

Benefits of Using the 3284259 Pressure Sensing Line

Incorporating the 3284259 Pressure Sensing Line into a truck’s system can lead to improved efficiency and reliability. By providing accurate and timely pressure data, the line allows the ECU to make more informed decisions, which can result in better fuel economy, reduced emissions, and extended component lifespan. For fleet operators, this can translate into cost savings through lower maintenance requirements and reduced downtime 2.

Installation and Integration

When installing the 3284259 Pressure Sensing Line, it is important to follow manufacturer guidelines to ensure compatibility with the truck’s existing systems. The installation process involves connecting the line to the appropriate sensors and the ECU, securing all connections, and testing the system to confirm that pressure readings are accurate and consistent. Best practices include using the correct tools and techniques to avoid damaging the line or its connections.

Troubleshooting Common Issues

Typical problems with pressure sensing lines may include leaks, inaccurate readings, or complete failure of the line. Diagnostic steps involve checking all connections for tightness and integrity, verifying that the line is free from obstructions, and ensuring that the sensors and ECU are functioning correctly. Solutions may range from simple repairs, such as tightening a connection, to replacing a faulty sensor or the line itself.

Maintenance Tips

To ensure the longevity and optimal performance of the 3284259 Pressure Sensing Line, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage, and cleaning the line and its connections to prevent buildup that could affect performance. Following the manufacturer’s recommended inspection intervals and care instructions will help maintain the line’s effectiveness and the overall health of the truck’s system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to advancing technology and improving efficiency is evident in its wide range of products, including the 3284259 Pressure Sensing Line 3.

Pressure Sensing Line (Part 3284259) in Cummins Engines

The Pressure Sensing Line (Part 3284259) is a critical component in Cummins engines, facilitating the accurate monitoring of pressure within the engine’s systems. This part is integral to the M11 CELECT PLUS engine, ensuring that the engine operates efficiently and safely by providing real-time data on pressure levels.

M11 CELECT PLUS Engine

In the M11 CELECT PLUS engine, the Pressure Sensing Line is designed to connect to various pressure sensors throughout the engine. This connection allows for the transmission of pressure data to the engine control unit (ECU), which then adjusts engine parameters to maintain optimal performance. The precision of this part is crucial for the engine’s ability to respond to changes in operating conditions, ensuring both efficiency and reliability.

The Pressure Sensing Line is engineered to withstand the high pressures and temperatures typical of engine environments, making it a durable and reliable component. Its design ensures minimal resistance to fluid flow, which is essential for maintaining accurate pressure readings. This part is typically made from high-quality materials that resist corrosion and degradation, ensuring long-term performance and reliability.

The integration of the Pressure Sensing Line into the M11 CELECT PLUS engine is a testament to Cummins’ commitment to quality and innovation. By providing a reliable means of pressure monitoring, this part helps to ensure that the engine operates at peak efficiency, reducing the risk of mechanical failure and extending the engine’s lifespan.

Role of Part 3284259 Pressure Sensing Line in Engine Systems

The Part 3284259 Pressure Sensing Line is integral to the efficient operation of various engine components. Its primary function is to transmit pressure readings from different parts of the engine to the control unit, ensuring that the engine operates within optimal parameters.

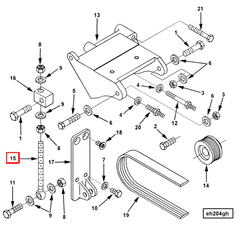

Integration with Mounting Components

When installed, the Pressure Sensing Line connects to the mounting brackets that secure the engine to the vehicle’s chassis. This connection allows for the monitoring of pressure changes that may occur due to engine vibrations or shifts in the engine’s position. By providing real-time data, the sensing line helps in making necessary adjustments to maintain engine stability and performance.

Interaction with the Alternator

The alternator, responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems, also benefits from the Pressure Sensing Line. The line monitors the pressure within the alternator’s cooling system, ensuring that it remains within specified limits. This is particularly important during high-load conditions, where the alternator works harder and generates more heat. The Pressure Sensing Line helps prevent overheating by allowing the control unit to adjust the alternator’s operation as needed.

Overall System Benefits

Incorporating the Pressure Sensing Line into these engine systems enhances overall performance and reliability. It allows for proactive management of potential issues, reducing the risk of component failure and improving the longevity of the engine and its associated parts.

Conclusion

The 3284259 Pressure Sensing Line by Cummins is a vital component in the efficient and reliable operation of commercial trucks. By accurately monitoring and transmitting pressure data, this part ensures that the engine and other critical systems operate within optimal parameters, leading to improved fuel economy, reduced emissions, and extended component lifespan. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Douglas R Carroll, Energy Efficiency of Vehicles, SAE International, 2020.

↩ ↩ -

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics, Creative Commons, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.