This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3250869 Adjusting Link End is a critical component in the suspension systems of commercial trucks, designed to facilitate the adjustment of suspension components for optimal performance and stability 1. This part ensures the efficiency and safety of truck operations by enabling precise adjustments to the suspension system.

Basic Concepts and Functionality

Adjusting link ends are essential for the suspension system of a truck, providing connection points for various suspension components 2. They allow for the fine-tuning of suspension geometry, which is vital for maintaining vehicle stability, load-carrying capacity, and ride comfort. The Cummins 3250869 Adjusting Link End connects to other suspension parts, enabling adjustments that affect the truck’s handling characteristics and overall performance.

Purpose and Role in Truck Operation

The Cummins 3250869 Adjusting Link End enhances the functionality of the truck’s suspension system by allowing for adjustments that adapt to different load conditions and road surfaces 3. This adaptability contributes to improved vehicle stability, better load distribution, and enhanced ride quality, which are crucial for the efficient and safe operation of commercial trucks.

Key Features

The Cummins 3250869 Adjusting Link End is characterized by its robust design and high-quality materials, contributing to its durability and performance 4. Key features include a precision-machined surface for a secure fit, corrosion-resistant coatings to extend lifespan, and a design that allows for easy adjustment and maintenance. These features ensure the part can withstand the rigors of commercial truck use while providing reliable performance.

Benefits

The use of the Cummins 3250869 Adjusting Link End offers several benefits. It contributes to improved suspension performance by allowing for precise adjustments that optimize the truck’s handling and stability. Additionally, its durable construction ensures long-term reliability, reducing the need for frequent replacements. Enhanced stability and performance can lead to safer operations and potentially lower maintenance costs over time.

Installation Process

Installing the Cummins 3250869 Adjusting Link End requires careful attention to ensure proper fit and function. The process involves securing the link end to the appropriate suspension components using the correct tools and following manufacturer guidelines. It is important to ensure that all connections are tight and that adjustments are made according to the vehicle’s specifications to achieve the desired suspension performance.

Common Issues and Troubleshooting

Common issues with the Cummins 3250869 Adjusting Link End may include wear and tear, misalignment, or corrosion. Troubleshooting steps can involve inspecting the part for signs of damage, ensuring that all connections are secure, and making necessary adjustments to the suspension system. Regular checks and maintenance can help prevent issues and ensure the part continues to function correctly.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3250869 Adjusting Link End, regular maintenance is recommended. This includes inspecting the part for signs of wear or damage, ensuring that all connections are secure, and making adjustments as needed to maintain the desired suspension performance. Keeping the part clean and free from corrosion can also contribute to its durability.

Compatibility and Applications

The Cummins 3250869 Adjusting Link End is designed for use in various truck models, offering versatility in its applications. Its compatibility with different commercial vehicles allows it to be a valuable component in maintaining the performance and safety of a wide range of trucks. Specific compatibility and application details should be consulted to ensure proper fit and function within the intended vehicle.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the industry for quality and innovation, Cummins is committed to providing reliable and efficient components for commercial vehicles. Their focus on research and development ensures that their products, like the Cummins 3250869 Adjusting Link End, meet the high standards required for modern truck operations.

Role of Part 3250869 Adjusting Link End in Engine Systems

The 3250869 Adjusting Link End is integral to the precise alignment and operation of various engine components. Its primary function is to facilitate the fine-tuning of connections between different parts, ensuring optimal performance and efficiency.

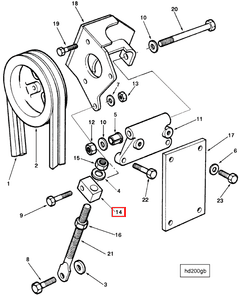

Alternator and Its Mounting Components

In systems involving the alternator, the 3250869 Adjusting Link End plays a significant role in the alternator bracket mounting and alternator link mounting. It allows for the fine adjustment of the alternator’s position relative to the engine, which is essential for maintaining the correct belt tension. This, in turn, ensures efficient power generation and reduces wear on the alternator and associated components.

Hydraulic Pump and Auxiliary Systems

For hydraulic pumps and auxiliary systems, the Adjusting Link End is used in the mounting processes to ensure that these components are aligned correctly with the engine. Proper alignment is vital for the hydraulic pump to operate efficiently, providing the necessary pressure and flow for various engine functions. Similarly, auxiliary pumps benefit from precise mounting, which enhances their performance and longevity.

Engine-Driven Components

In engine-driven components such as the alternator and hydraulic pump, the 3250869 Adjusting Link End aids in the fine-tuning of their operational parameters. By allowing minor adjustments in the mounting and linkage, it helps in achieving the desired output and efficiency from these components. This is particularly important in high-performance engines where even slight misalignments can lead to significant inefficiencies.

Electrical and Mechanical Integration

The Adjusting Link End also facilitates the integration of electrical components like the alternator with mechanical components such as the engine mounting and auxiliary pump systems. This integration is crucial for the seamless operation of the engine, ensuring that all components work in harmony to deliver optimal performance.

Summary of Component Interactions

- Alternator Bracket Mounting: Ensures the alternator is correctly positioned for efficient power generation.

- Alternator Link Mounting: Maintains proper belt tension for the alternator.

- Hydraulic Pump Mounting: Aligns the hydraulic pump for efficient pressure and flow.

- Auxiliary Pump Systems: Enhances the performance and longevity of auxiliary pumps.

- Engine Mounting: Integrates electrical and mechanical components for seamless engine operation.

The 3250869 Adjusting Link End is a versatile component that contributes to the efficient and reliable operation of various engine systems by allowing for precise adjustments and alignments.

Conclusion

The Cummins 3250869 Adjusting Link End is a vital component in the suspension and engine systems of commercial trucks. Its role in facilitating precise adjustments ensures optimal performance, stability, and efficiency. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to safer and more reliable truck operations.

-

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Singh, D. K. Dictionary of Mechanical Engineering. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.