This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3250866 Adjusting Link End is a critical component in the suspension systems of commercial trucks, designed to facilitate the adjustment of suspension links. This ensures that the truck maintains proper alignment and suspension integrity, contributing to the overall performance, safety, and longevity of the vehicle’s suspension system 1.

Function and Operation

The Adjusting Link End operates within the truck’s suspension system by allowing for the fine-tuning of suspension links. This adjustment is essential for maintaining the correct alignment of the truck’s axles, ensuring that the suspension system operates efficiently. By enabling precise adjustments, the Adjusting Link End helps preserve the integrity of the suspension, which is vital for the truck’s handling, stability, and ride quality 2.

Key Features

The Cummins 3250866 Adjusting Link End is characterized by several key features that enhance its performance. It is typically made from high-strength materials, ensuring durability under the demanding conditions of commercial truck operations. The design includes features that facilitate easy adjustment and secure attachment to suspension links. Additionally, it may incorporate unique characteristics such as corrosion-resistant coatings or specialized threading to improve its functionality and longevity 3.

Benefits

The use of the Adjusting Link End offers several benefits. It contributes to improved ride quality by ensuring that the suspension system remains properly aligned. Enhanced durability is another advantage, as the robust construction of the Adjusting Link End allows it to withstand the rigors of commercial truck use. Furthermore, by maintaining proper alignment and suspension integrity, the Adjusting Link End plays a role in the overall stability and handling of the vehicle 4.

Installation Process

Installing the Cummins 3250866 Adjusting Link End requires following a step-by-step process to ensure optimal performance. The procedure involves using specific tools to attach the Adjusting Link End to the suspension link, making the necessary adjustments to achieve the desired alignment, and securing the component in place. It is important to conduct alignment checks throughout the installation process to verify that the suspension system is correctly configured 5.

Maintenance and Troubleshooting

To ensure the longevity and performance of the Adjusting Link End, regular maintenance is recommended. This includes inspecting the component for signs of wear or damage, cleaning it to remove any debris or contaminants, and making adjustments as needed to maintain proper alignment. Common issues that may arise with the Adjusting Link End include misalignment or wear, which can often be addressed through proper maintenance practices and, if necessary, replacement of the component 6.

Compatibility and Applications

The Cummins 3250866 Adjusting Link End is designed for use in specific types of trucks and suspension systems. It finds applications in various commercial truck models, where it plays a role in the suspension system by allowing for precise adjustments that contribute to the vehicle’s performance and safety 7.

Safety Considerations

When working with the Adjusting Link End, it is important to observe safety guidelines and precautions. This includes ensuring that the vehicle is properly supported and secured before beginning any work, using the correct tools and procedures for installation and maintenance, and following manufacturer recommendations for handling and usage. Adhering to these safety considerations helps to protect both the technician and the vehicle 8.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company has a history of producing reliable and high-performance truck components, including the Cummins 3250866 Adjusting Link End. Cummins’ reputation for excellence is built on its dedication to advancing technology and meeting the needs of its customers in the commercial trucking sector 9.

Understanding the Role of Part 3250866 Adjusting Link End in Engine Systems

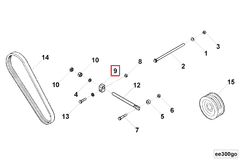

In the intricate dance of engine components, the Adjusting Link End (part 3250866) plays a significant role in ensuring the smooth operation of various systems. This component is integral to the proper functioning of the Alternator Link Mounting and Alternator Mounting systems.

Integration with Alternator Systems

The Adjusting Link End is designed to work in conjunction with the Alternator Link Mounting and Alternator Mounting components. Its primary function is to provide the necessary adjustments to maintain the correct tension and alignment of the alternator belt. This ensures that the alternator operates efficiently, generating the required electrical power to support the engine’s electrical systems 10.

Base Parts and Mounting Considerations

When installed on Base Parts, the Adjusting Link End allows for fine-tuning of the alternator’s position. This is particularly important during the initial setup or when performing maintenance on the engine. Proper alignment and tension are essential to prevent wear and tear on the alternator and its associated components 11.

Comprehensive System Interaction

Beyond the alternator, the Adjusting Link End also interacts with other Mounting components within the engine system. Its adjustable nature enables engineers and mechanics to make precise modifications, ensuring that all interconnected parts operate harmoniously. This is especially vital in high-performance engines where even minor misalignments can lead to significant issues 12.

Practical Application

In practical terms, the Adjusting Link End is a tool that facilitates the easy adjustment of the alternator’s position and tension. This is achieved without the need for extensive disassembly or reassembly of the engine components. Such functionality is invaluable during routine maintenance checks or when upgrading engine parts 13.

Conclusion

By understanding the role of the Adjusting Link End within these systems, engineers and mechanics can ensure optimal performance and longevity of the engine’s electrical components. The Cummins 3250866 Adjusting Link End is a testament to the brand’s commitment to quality and precision engineering, playing a critical role in the smooth and efficient operation of various engine systems.

-

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 4367324.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 4367324.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 4367324.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 4367324.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 4367324.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.