This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

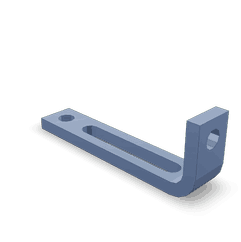

The Cummins 3062643 Adjusting Link is a component designed for use in commercial trucks. Its purpose is to facilitate the proper alignment and tension within the truck’s system, contributing to the efficient operation of the vehicle. This part is significant in ensuring that the truck’s components function harmoniously, thereby supporting overall performance and reliability 1.

Function and Operation

The Cummins 3062643 Adjusting Link operates by maintaining the correct alignment and tension within the truck’s system. It is positioned to connect various components, allowing for adjustments that ensure optimal performance. By doing so, the Adjusting Link helps in reducing wear and tear on other parts, thus contributing to the longevity and efficiency of the truck 2.

Key Features

The Cummins 3062643 Adjusting Link is characterized by its robust design and the materials used in its construction. It is made from high-quality steel, which provides durability and resistance to the stresses encountered in commercial truck operations. Additionally, the link features precise machining and a corrosion-resistant coating, enhancing its performance and longevity in various operating conditions.

Role in Truck Operation

In the operation of a commercial truck, the Cummins 3062643 Adjusting Link interacts with other components to ensure smooth and efficient performance. It plays a role in maintaining the alignment of parts, which is vital for the truck’s stability and handling. Furthermore, by ensuring proper tension, it contributes to the efficient transfer of power and reduces the likelihood of component failure.

Benefits

The Cummins 3062643 Adjusting Link offers several benefits, including improved performance, durability, and ease of maintenance. Its design and materials contribute to a longer service life, while its role in maintaining alignment and tension leads to enhanced truck performance. Additionally, the link is designed for straightforward installation and maintenance, reducing downtime and operational costs.

Installation Process

Installing the Cummins 3062643 Adjusting Link requires careful attention to ensure proper function and safety. The process involves securing the link in its designated position, making necessary adjustments to achieve the correct alignment and tension, and verifying that all connections are secure. Tools such as wrenches and alignment gauges may be required, and it is important to follow manufacturer guidelines to ensure correct installation.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3062643 Adjusting Link, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring that all connections remain secure, and applying lubrication as necessary to moving parts. Adhering to these maintenance practices can help prevent issues and extend the service life of the link.

Troubleshooting Common Issues

Common issues with the Cummins 3062643 Adjusting Link may include misalignment, tension problems, or wear and tear. Troubleshooting these issues involves inspecting the link and its connections for any signs of damage or improper installation. Adjustments may be necessary to correct alignment or tension, and in cases of significant wear, replacement of the link might be required.

Manufacturer Information

Cummins Inc. is a leading manufacturer in the diesel engine industry, known for its commitment to quality and innovation. With a history of providing reliable and high-performance engine components, Cummins has established a reputation for excellence in the commercial truck sector. The company’s dedication to research and development ensures that its products, including the Cummins 3062643 Adjusting Link, meet the demanding requirements of modern commercial truck operations.

Cummins Part 3062643: Adjusting Link in N14 Engines

The Cummins part 3062643, known as the Adjusting Link, is a crucial component in the N14 engine family. This part is integral to the operation of both the N14 CELECT PLUS and N14 MECHANICAL engines, ensuring precise control and functionality.

In the N14 CELECT PLUS engine, the Adjusting Link is used to fine-tune the engine’s performance by adjusting the valve timing. This is particularly important for maintaining the engine’s efficiency and responsiveness, especially under varying load conditions. The CELECT PLUS variant benefits from this part’s precision, as it helps in achieving optimal combustion timing, which is critical for electronic control systems.

Similarly, in the N14 MECHANICAL engine, the Adjusting Link plays a vital role in the mechanical valve train system. Here, it ensures that the valves open and close at the correct intervals, which is essential for the engine’s overall performance and longevity. The mechanical nature of this engine relies heavily on the accuracy of such components to function smoothly and reliably.

Both engines, despite their different control systems, share the commonality of requiring precise valve timing adjustments. The part 3062643, being a standardized component, fits seamlessly into both the N14 CELECT PLUS and N14 MECHANICAL engines, ensuring that the engine’s mechanical and electronic systems operate in harmony.

Role of Part 3062643 Adjusting Link in Engine Systems

Part 3062643, the Adjusting Link, is integral to the precise functioning of various engine components. Its primary role is to facilitate the fine-tuning and alignment of mechanical parts, ensuring optimal performance and longevity of the engine system.

Alternator Mounting

In the alternator mounting system, the Adjusting Link allows for the precise positioning of the alternator. This ensures that the alternator is correctly aligned with the engine’s crankshaft pulley. Proper alignment is essential for efficient power transfer and minimizes wear on both the alternator and the belt drive system. The Adjusting Link enables mechanics to make minor adjustments that can significantly impact the alternator’s efficiency and the overall electrical output of the engine.

Alternator Mounting Arrangement

The alternator mounting arrangement benefits greatly from the use of the Adjusting Link. This component allows for the customization of the alternator’s position relative to the engine block and other surrounding components. By enabling slight modifications in the alternator’s placement, the Adjusting Link helps in reducing vibrations and ensuring a stable operation. This is particularly important in high-performance engines where even minor misalignments can lead to increased wear and reduced efficiency.

General Mounting Applications

Beyond the alternator, the Adjusting Link is used in various mounting applications throughout the engine system. Whether it’s mounting sensors, auxiliary components, or other critical parts, the Adjusting Link provides the necessary flexibility to fine-tune the positioning. This is vital for maintaining the correct clearances and ensuring that all components operate within their specified parameters. The ability to make precise adjustments can prevent issues such as component interference, excessive wear, and potential failures.

Alternator Mounting Integration

When integrating the alternator into the engine system, the Adjusting Link plays a key role in achieving the perfect balance between tension and alignment. It allows for the alternator belt to be tensioned correctly, which is essential for efficient power transmission. Proper belt tension ensures that the alternator operates at its optimal efficiency, providing consistent electrical power to the engine’s electrical systems. The Adjusting Link’s capability to facilitate these adjustments is fundamental to the reliable operation of the alternator within the engine system.

Conclusion

The Cummins 3062643 Adjusting Link is a vital component in the operation and maintenance of commercial trucks and engines. Its role in ensuring proper alignment and tension within the system contributes significantly to the vehicle’s performance, reliability, and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring that it continues to support the efficient operation of the truck and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.