This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3055043 Adjusting Link Bracket is a component designed for use in the suspension systems of commercial trucks. Its purpose is to facilitate the adjustment and maintenance of the suspension system, ensuring optimal performance and stability of the vehicle under various load conditions.

Purpose and Function

The primary role of the Adjusting Link Bracket in the suspension system of heavy-duty trucks is to provide a means for fine-tuning the suspension geometry. This adjustment capability contributes to the overall performance and stability of the vehicle by allowing for precise control over the suspension’s behavior. Proper adjustment can lead to improved ride quality, better load handling, and enhanced safety during operation 1.

Key Features

The Cummins 3055043 Adjusting Link Bracket is constructed with durability and functionality in mind. It is typically made from high-strength materials, such as steel, to withstand the rigors of heavy-duty truck operations. The design includes specific mounting points that allow for secure attachment to the truck’s frame and suspension components. Unique characteristics of this bracket may include corrosion-resistant coatings or treatments to enhance its longevity in harsh operating environments.

Benefits

Using the Cummins 3055043 Adjusting Link Bracket offers several advantages. It contributes to improved suspension performance by enabling precise adjustments that can optimize the truck’s handling characteristics. Additionally, it enhances the truck’s load-carrying capacity by ensuring the suspension system operates within its designed parameters. The durability of the bracket means it can withstand the stresses of heavy-duty use, providing long-term reliability.

Installation Process

Installing the Adjusting Link Bracket requires careful attention to detail to ensure a secure fit. The process involves attaching the bracket to the truck’s frame and suspension components using the provided mounting points. Tools such as wrenches and torque wrenches may be necessary to secure the bracket properly. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening or under-tightening, which could affect the bracket’s performance and longevity.

Maintenance Tips

Regular inspection and maintenance of the Adjusting Link Bracket are crucial for ensuring optimal performance and longevity. It is recommended to check the bracket for signs of wear or damage during routine maintenance checks. Look for any cracks, corrosion, or loose mounting points that could indicate the need for repair or replacement. Keeping the bracket clean and free from debris can also help maintain its functionality.

Troubleshooting Common Issues

Common problems associated with the Adjusting Link Bracket may include misalignment or excessive wear. Misalignment can often be corrected by re-adjusting the bracket according to the manufacturer’s specifications. Excessive wear may require replacement of the bracket or other suspension components. Regular inspections can help identify these issues early, allowing for timely corrections and preventing more significant problems down the line.

Manufacturer Information

Cummins Inc. is a well-established company in the automotive industry, known for its commitment to producing high-quality components. With a history of innovation and excellence, Cummins has built a reputation for reliability and performance in the commercial truck sector. The company’s dedication to quality is evident in the design and construction of components like the 3055043 Adjusting Link Bracket, ensuring they meet the demanding requirements of heavy-duty truck applications.

Role of Part 3055043 Adjusting Link Bracket in Engine Systems

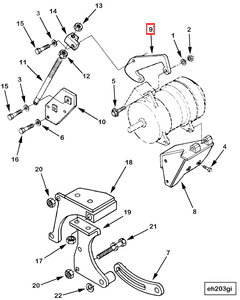

The Adjusting Link Bracket (part 3055043) is an integral component in the assembly and operation of various engine systems, particularly when interfacing with the mounting and alternator components.

Interaction with Mounting Components

In engine systems, the Adjusting Link Bracket is employed to provide precise alignment and secure attachment points for mounting components. This bracket ensures that the mounting points are correctly spaced and aligned, which is essential for the stable installation of engine components. It allows for minor adjustments to be made during the installation process, ensuring that all parts are properly aligned and that the engine operates within specified tolerances. This is particularly important in high-vibration environments where maintaining precise alignment can prevent undue stress on engine mounts and other supporting structures.

Integration with the Alternator

The Alternator, a key component responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems, also benefits from the Adjusting Link Bracket. The bracket facilitates the proper positioning of the alternator in relation to the engine and other components. It allows for fine-tuning of the alternator’s placement, ensuring optimal belt tension and efficient operation. This is vital for maintaining the alternator’s performance and longevity, as improper alignment can lead to increased wear on the drive belt and reduced efficiency in power generation.

Conclusion

In summary, the Adjusting Link Bracket (part 3055043) plays a significant role in ensuring the precise alignment and secure installation of both mounting components and the alternator within engine systems. Its ability to allow for minor adjustments during installation contributes to the overall stability and efficiency of the engine’s operation.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.