This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Adjusting Link Adjuster, Part #3054504 by Cummins, is a component designed to facilitate precise adjustments within the mechanical systems of trucks. Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry, produces this adjuster to enhance the functionality and efficiency of truck mechanics. This part is integral to maintaining the optimal performance of truck engines by allowing for fine-tuned adjustments that can adapt to varying operational conditions.

Function and Operation

The Adjusting Link Adjuster operates by connecting various mechanical components within the truck’s system, enabling adjustments that are crucial for the proper functioning of the engine and other systems. It interacts with components such as the valve train, allowing for the adjustment of valve clearances. This interaction ensures that the valves open and close at the correct times, which is vital for the engine’s combustion process. The adjuster’s design permits easy modification of the link length, which in turn affects the timing and efficiency of valve operations.

Purpose of the Adjusting Link Adjuster

The Adjusting Link Adjuster plays a role in the overall operation of a truck by ensuring that the engine components work in harmony. Its primary function is to maintain the correct valve clearance, which is necessary for efficient engine performance. By allowing for precise adjustments, it helps in optimizing the engine’s combustion efficiency, thereby contributing to better fuel economy and reduced emissions. Additionally, it aids in prolonging the lifespan of engine components by ensuring they operate within their designed parameters 1.

Key Features

The Adjusting Link Adjuster is characterized by several design elements that enhance its effectiveness and reliability. These include a robust construction that can withstand the high stresses and temperatures within an engine environment. It also features a precise adjustment mechanism that allows for fine-tuning of the link length. The material used in its construction is resistant to wear and corrosion, ensuring durability over time. Additionally, the design incorporates ease of access for maintenance, which simplifies the adjustment process.

Benefits

The Adjusting Link Adjuster offers several advantages that contribute to improved engine performance and maintenance ease. By allowing for precise adjustments, it helps in maintaining optimal valve clearance, which is crucial for efficient engine operation. This leads to better fuel efficiency and reduced emissions. Furthermore, its design facilitates easier maintenance, reducing downtime and labor costs. The durability of the adjuster also contributes to the longevity of the engine components it interacts with 2.

Installation Process

Installing the Adjusting Link Adjuster requires careful attention to detail to ensure proper function. The process involves disconnecting the old adjuster, if present, and connecting the new one in its place. Tools required may include a wrench for tightening connections and a feeler gauge for checking valve clearances. It is important to follow the manufacturer’s instructions closely to ensure that the adjuster is installed correctly and that all connections are secure.

Troubleshooting Common Issues

Common issues with the Adjusting Link Adjuster may include incorrect valve clearances or difficulty in adjusting the link length. These problems can often be resolved by rechecking the installation process and ensuring that all connections are secure. If the adjuster itself is faulty, it may need to be replaced. Regular inspection and maintenance can help in identifying potential issues before they become significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Adjusting Link Adjuster, regular maintenance is recommended. This includes checking the valve clearances at regular intervals and ensuring that the adjuster is functioning correctly. Cleaning the adjuster and its surrounding components can also help in preventing buildup that may affect its operation. Following the manufacturer’s maintenance schedule will help in keeping the adjuster in good working condition.

Safety Considerations

When working with the Adjusting Link Adjuster, it is important to observe safety guidelines to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, when handling the component. Ensuring that the engine is cool before beginning any work is also crucial. Additionally, following the manufacturer’s instructions for installation and maintenance will help in avoiding potential hazards.

Cummins Overview

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance engine components, Cummins has built a reputation for excellence. The company’s focus on research and development ensures that its products, including the Adjusting Link Adjuster, meet the highest standards of quality and performance. Cummins’ dedication to customer satisfaction and technological advancement makes it a trusted name in the industry.

Cummins Part 3054504: Adjusting Link Adjuster for L10 Engines

The Cummins part 3054504, known as the Adjusting Link Adjuster, is a critical component in the operation of the L10 series engines, specifically the L10 GAS and L10 MECHANICAL variants. This part plays a pivotal role in maintaining the precise alignment and functionality of the engine’s valve train system.

For the L10 GAS engine, the Adjusting Link Adjuster ensures that the valves open and close at the correct times, which is essential for optimal combustion efficiency and performance. This is particularly important in gas engines where precise timing can significantly affect fuel economy and emissions.

In the L10 MECHANICAL engine, the Adjusting Link Adjuster is equally crucial. It helps in maintaining the mechanical linkage between the camshaft and the valve train, ensuring that the valves operate smoothly and reliably under varying load conditions. This mechanical precision is vital for the durability and longevity of the engine.

Both engines benefit from the use of the Adjusting Link Adjuster as it allows for fine-tuning and adjustments to be made without the need for extensive disassembly. This makes maintenance and repairs more efficient and less time-consuming, contributing to the overall reliability of the L10 series engines.

Role of Part 3054504 Adjusting Link Adjuster in Engine Systems

The Adjusting Link Adjuster (part 3054504) is an essential component in the synchronization and alignment of various engine systems. Its primary function is to facilitate precise adjustments within the engine’s mechanical framework, ensuring optimal performance and efficiency.

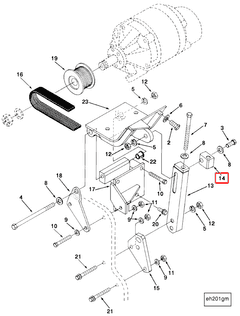

Integration with Alternator Location and Mounting

When considering the alternator location and its mounting, the Adjusting Link Adjuster plays a significant role. It allows for fine-tuning the positioning of the alternator relative to the engine’s crankshaft. This adjustment ensures that the alternator operates within the ideal range for efficient power generation. Proper alignment minimizes wear on the drive belt and reduces the risk of alternator failure due to misalignment.

Ensuring Stability and Efficiency

The adjuster contributes to the stability of the alternator mounting. By enabling micro-adjustments, it helps maintain consistent tension on the drive belt, which is vital for the alternator’s efficient operation. This, in turn, ensures a steady supply of electrical power to the engine’s components, supporting overall engine performance.

Facilitating Maintenance and Repairs

During maintenance or repairs, the Adjusting Link Adjuster simplifies the process of realigning the alternator. Whether replacing the alternator or performing routine checks, the adjuster allows mechanics to make necessary adjustments quickly and accurately. This capability is particularly beneficial in high-performance engines where precision is paramount.

Enhancing Engine Longevity

By ensuring that the alternator is correctly aligned and tensioned, the Adjusting Link Adjuster contributes to the longevity of both the alternator and the engine itself. Reduced strain on the drive belt and alternator components leads to fewer replacements and lower maintenance costs over the engine’s lifespan.

Conclusion

In summary, the Adjusting Link Adjuster (part 3054504) is a key component in maintaining the precise alignment and tension required for the efficient operation of the alternator within engine systems. Its role in facilitating adjustments enhances both performance and durability, making it an invaluable part of the engine’s mechanical setup. Regular maintenance and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.