This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3537376 Oil Seal is a component designed to prevent lubricant leakage in commercial trucks. Its role is significant in maintaining the efficiency and reliability of the truck’s engine or transmission system. By ensuring that lubricants remain within the system, this part contributes to the smooth operation and longevity of the vehicle.

Basic Concepts of Oil Seals

An oil seal, also known as a rotary shaft seal, is a mechanical device used to prevent the leakage of lubricants from rotating shafts. It functions by creating a barrier between the rotating and stationary parts of machinery. The importance of oil seals in vehicles and machinery lies in their ability to maintain lubricant levels, which are crucial for reducing friction and wear on moving parts. Proper sealing ensures that lubricants do not escape, thereby preserving the integrity and performance of the system 1.

Purpose of the Cummins 3537376 Oil Seal

The Cummins 3537376 Oil Seal plays a specific role in the operation of a truck by sealing the interface between rotating and stationary components within the engine or transmission. This seal helps maintain the necessary lubricant levels, which are vital for reducing friction and wear. By ensuring that lubricants stay within the system, the oil seal contributes to the overall efficiency and reliability of the truck’s engine or transmission system.

Key Features

The Cummins 3537376 Oil Seal is characterized by several key features that enhance its performance and durability. These include its material composition, typically made from high-quality rubber compounds that offer excellent resistance to oil and wear. The design elements of the seal, such as its lip configuration and spring support, ensure a tight fit and effective sealing. Additionally, any unique characteristics, such as anti-rotation features, further contribute to its reliability and longevity.

Benefits

Using the Cummins 3537376 Oil Seal offers several benefits. These include improved engine performance due to consistent lubrication, reduced maintenance costs as a result of fewer lubricant leaks, and increased reliability of the truck’s engine or transmission system. These benefits contribute to the overall operation of the truck by ensuring that the engine runs smoothly and efficiently, with minimal downtime and maintenance requirements.

Installation Considerations

Proper installation of the Cummins 3537376 Oil Seal is crucial for ensuring optimal performance and longevity. Guidelines and best practices for installation include ensuring the sealing surface is clean and free of contaminants, using the correct installation tools to avoid damage, and verifying that the seal is properly seated. Attention to these details during installation helps prevent issues such as leaks and premature wear 2.

Troubleshooting and Maintenance

To troubleshoot common issues related to the Cummins 3537376 Oil Seal, it is important to inspect the seal regularly for signs of wear, damage, or leakage. Tips for regular maintenance include checking the seal during routine oil changes, ensuring that the sealing surface remains clean, and replacing the seal if any signs of wear or damage are detected. These practices help ensure the seal remains in good working condition and continues to perform its intended function effectively.

Common Failure Modes

Common failure modes associated with oil seals include wear, leakage, and damage from contaminants. Signs of wear may include grooves or cracks on the seal lip, while leakage can be identified by lubricant stains around the seal area. Taking appropriate action, such as cleaning the sealing surface, replacing worn seals, or addressing contamination issues, can help mitigate these failure modes and maintain the seal’s effectiveness.

About Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its history of innovation and commitment to quality. The company offers a wide range of products, including engines, transmissions, and aftermarket parts, designed to meet the demanding requirements of commercial vehicles. Cummins’ reputation for reliability and performance is built on its dedication to engineering excellence and customer satisfaction 3.

Cummins Oil Seal 3537376 Compatibility with Engine Models

The Cummins Oil Seal part number 3537376 is designed to fit seamlessly within various engine models, ensuring optimal performance and longevity. This oil seal is engineered to provide a reliable barrier against oil leaks, which is crucial for maintaining engine efficiency and preventing contamination.

Engine Models

- 6C8.3: This oil seal is specifically engineered to fit the 6C8.3 engine model. Its precision fit ensures that it effectively seals the engine’s moving parts, preventing oil from leaking out and ensuring that the engine operates smoothly.

The 3537376 oil seal is a critical component in maintaining the integrity of the engine’s lubrication system. Its compatibility with the 6C8.3 engine model underscores its importance in preserving engine performance and reliability.

Role of Part 3537376 Oil Seal in Engine Systems

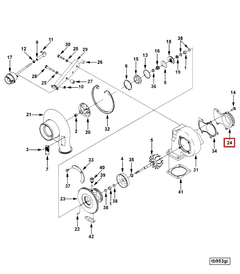

The part 3537376 Oil Seal is an essential component in maintaining the integrity and performance of various engine systems, particularly those involving turbochargers and related assemblies.

In an aftermarket turbocharger, the oil seal ensures that lubrication is effectively managed between rotating and stationary parts. This prevents oil leakage, which could lead to inefficient operation and potential damage to the turbocharger.

When integrated into a pre-set turbine housing kit, the oil seal plays a significant role in sealing the interface between the turbocharger and the turbine housing. This sealing is vital for maintaining the pressure differentials necessary for optimal turbocharger performance.

Within the turbine housing, the oil seal helps in containing lubrication within the designated pathways, ensuring that the turbine wheel operates smoothly without excessive friction or wear.

In a standard turbocharger, the oil seal is positioned to prevent oil from escaping into the compressor or turbine sections, which could otherwise contaminate the airflow and reduce efficiency.

For turbocharger aftermarket applications, where performance enhancements are often sought, the oil seal’s role becomes even more pronounced. It ensures that the increased stresses and temperatures do not lead to oil leakage, thereby preserving the turbocharger’s longevity and performance.

In a turbocharger kit, which may include various components designed to work in unison, the oil seal ensures that each part functions within its lubrication parameters, contributing to the overall reliability and efficiency of the kit.

The wastegate t/housing sub-assembly relies on the oil seal to maintain the integrity of the lubrication system. This is particularly important as the wastegate modulates the turbocharger’s boost levels, and any oil leakage could affect its operation.

Finally, in a wastegate turbine housing kit, the oil seal is instrumental in ensuring that the wastegate mechanism operates smoothly. By containing oil within the necessary channels, it helps in maintaining the precision and responsiveness of the wastegate, which is crucial for managing turbocharger boost levels effectively.

Conclusion

The Cummins 3537376 Oil Seal is a vital component in the maintenance and operation of commercial truck engines and transmissions. Its role in preventing lubricant leakage ensures the smooth operation and longevity of the vehicle. Proper installation, regular maintenance, and understanding common failure modes are essential for maximizing the effectiveness of this part. Cummins’ commitment to quality and innovation underscores the reliability and performance of the 3537376 Oil Seal in various engine systems.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Andrew Brown Jr. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4310645, ISX12 CM2350 X102.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.