This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

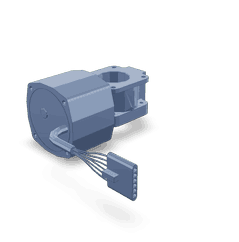

The Cummins 3970806 Actuator is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Actuators

An actuator is a device that converts energy into motion, playing a role in controlling a system or mechanism. Actuators can be categorized into various types, including hydraulic, pneumatic, electric, and thermal, each utilizing different energy sources to perform mechanical actions. In mechanical systems, actuators are integral for moving parts, adjusting settings, and enabling automated processes.

Role of the 3970806 Actuator in Truck Operation

The Cummins 3970806 Actuator is involved in the operation of specific systems within a truck. It interacts with various components to facilitate functions such as valve operation, which is crucial for engine performance. By precisely controlling the opening and closing of valves, the actuator contributes to the engine’s efficiency and power output 1.

Key Features

The 3970806 Actuator is characterized by several design elements and materials that enhance its performance. It is constructed with durable materials to withstand the rigors of commercial truck operation. Unique characteristics, such as its precision engineering and robust build, ensure reliable operation under demanding conditions.

Benefits of Using the 3970806 Actuator

Incorporating the 3970806 Actuator into a truck’s system offers several advantages. It contributes to improved engine efficiency by ensuring precise valve timing. Additionally, its reliable operation enhances the overall performance and reliability of the truck, reducing the likelihood of system failures.

Installation and Integration

Proper installation of the 3970806 Actuator is vital for its effective operation. Guidelines for installation include ensuring compatibility with the truck’s system and following manufacturer recommendations. Considerations such as alignment and secure mounting are important to prevent issues during operation.

Troubleshooting Common Issues

Common problems associated with the 3970806 Actuator may include malfunctions or failures in valve operation. Potential causes can range from electrical issues to mechanical wear. Recommended troubleshooting steps involve checking electrical connections, inspecting for physical damage, and ensuring proper system calibration.

Maintenance Tips

Regular maintenance practices are essential for the longevity and optimal performance of the 3970806 Actuator. Suggestions include periodic inspection for wear and tear, cleaning to remove contaminants, and ensuring all connections are secure. Adhering to a maintenance schedule helps prevent unexpected failures and extends the component’s lifespan.

Safety Considerations

When working with the 3970806 Actuator, it is important to observe safety guidelines and precautions. This includes ensuring the truck is powered down before beginning any work, using appropriate personal protective equipment, and following all manufacturer safety recommendations during handling, installation, and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles.

Role of 3970806 Actuator in Engine Systems

The 3970806 Actuator is an integral component in the orchestration of various engine systems, ensuring precise and efficient operation. Its primary function is to facilitate the dynamic adjustment of the air-fuel mixture within the engine, a task it accomplishes in conjunction with several key components.

Integration with the Air-Fuel Mixer

The Actuator works in tandem with the Air-Fuel Mixer to regulate the proportion of air and fuel entering the combustion chamber. By receiving signals from the Engine Control Unit (ECU), the Actuator adjusts the mixer’s settings, optimizing the air-fuel ratio for varying engine loads and operating conditions. This precise control is essential for maximizing engine performance and efficiency.

Coordination with the Fuel Control Module

In conjunction with the Fuel Control Module, the Actuator plays a pivotal role in modulating fuel delivery. The Actuator responds to inputs from sensors monitoring engine parameters such as temperature, load, and speed. It then adjusts the fuel injector’s operation, ensuring that the correct amount of fuel is delivered at the right time. This synergy between the Actuator and the Fuel Control Module is fundamental to achieving optimal combustion and minimizing emissions.

Interaction with the Fuel Control System

The Actuator is also a key player in the broader Fuel Control System. It interfaces with various sensors and the ECU to maintain a stable and efficient fuel supply. By fine-tuning the fuel injection timing and duration, the Actuator helps to maintain engine stability, especially under fluctuating operating conditions. This interaction is vital for ensuring smooth engine operation and responsiveness.

Role in the Actuator Kit

When part of an Actuator Kit, the 3970806 Actuator enhances the kit’s capability to provide comprehensive engine management. The kit typically includes additional components and sensors that work in concert with the Actuator to offer a more refined control over engine functions. This setup is particularly beneficial in high-performance or precision-demanding applications, where every nuance of engine operation can significantly impact overall performance.

Conclusion

The Cummins 3970806 Actuator is a versatile and essential component in modern engine systems. Its ability to interact with and influence the Air-Fuel Mixer, Fuel Control Module, and broader Fuel Control System underscores its importance in achieving efficient, responsive, and environmentally friendly engine operation.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.