This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To Accumulators In Truck Engines

An accumulator, often referred to as a pressure reservoir, is a crucial component in commercial truck engines, particularly in systems that rely on hydraulic or pneumatic power 3. It stores energy in the form of compressed gas or fluid, which can be released to perform work when needed. This stored energy helps maintain consistent pressure within the system, ensuring smooth and reliable operation.

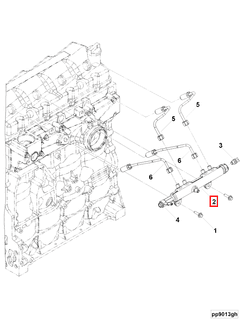

The Role Of The Cummins 5344767 Accumulator

The Cummins 5344767 accumulator is specifically designed to enhance the performance and efficiency of commercial truck engines. It plays a vital role in the engine’s hydraulic or pneumatic systems by:

- Maintaining System Pressure: The accumulator ensures that the system maintains a consistent pressure level, which is essential for the proper functioning of various engine components 4.

- Smoothing Out Pressure Fluctuations: By absorbing and releasing energy as needed, the accumulator helps to smooth out pressure fluctuations, reducing wear and tear on engine parts 1.

- Enhancing System Response: The accumulator improves the overall response time of the engine’s hydraulic or pneumatic systems, allowing for quicker and more precise control 2.

How The Cummins 5344767 Accumulator Works

The Cummins 5344767 accumulator operates by using a diaphragm or piston to separate the stored energy from the system fluid. When the system requires additional pressure, the accumulator releases the stored energy, maintaining consistent pressure levels. Conversely, when the system is under low demand, the accumulator recharges, storing energy for future use.

Importance Of The Cummins 5344767 Accumulator In Truck Operations

The Cummins 5344767 accumulator is essential for the efficient operation of commercial trucks. It ensures that the engine’s hydraulic or pneumatic systems function optimally, contributing to:

- Improved Fuel Efficiency: By maintaining consistent system pressure, the accumulator helps to improve fuel efficiency, reducing operating costs 3.

- Enhanced Reliability: The accumulator’s ability to smooth out pressure fluctuations and enhance system response contributes to the overall reliability of the engine 4.

- Reduced Wear And Tear: By absorbing and releasing energy as needed, the accumulator helps to reduce wear and tear on engine components, extending their lifespan 1.

Troubleshooting And Maintenance Of The Cummins 5344767 Accumulator

Proper maintenance and troubleshooting of the Cummins 5344767 accumulator are crucial for ensuring the longevity and efficiency of the engine’s hydraulic or pneumatic systems. Some key considerations include:

- Regular Inspection: Regularly inspect the accumulator for signs of wear, leaks, or damage. Replace any damaged components immediately to prevent system failure 2.

- Pressure Testing: Periodically test the accumulator’s pressure levels to ensure it is functioning correctly. If pressure levels are consistently low or high, the accumulator may need to be replaced 3.

- Fluid Maintenance: Ensure that the system fluid is clean and free of contaminants. Contaminated fluid can cause the accumulator to malfunction, leading to system failure 4.

About Cummins

Cummins is a leading global power leader that designs, manufactures, sells, and services a broad range of power systems. With a strong focus on innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. Their commitment to delivering reliable and efficient power solutions has made them a preferred choice for engineers, mechanics, truck drivers, and fleet operators worldwide.

Conclusion

The Cummins 5344767 accumulator is an essential component in commercial truck engines, ensuring consistent system pressure, smooth operation, and improved fuel efficiency. By understanding the role and function of the accumulator, as well as implementing proper maintenance and troubleshooting practices, engineers, mechanics, truck drivers, and fleet operators can ensure the longevity and efficiency of their engines.

-

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ ↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ ↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ ↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.