This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4307128 Accumulator is a component designed to enhance the operation of hydraulic systems in commercial trucks. Its role is to store and release hydraulic fluid, contributing to the overall efficiency and performance of the truck’s hydraulic operations.

Basic Concepts of an Accumulator

An accumulator is a device used in hydraulic systems to store energy in the form of pressurized fluid. It functions by maintaining system pressure, absorbing shocks, and smoothing out pressure fluctuations. In heavy-duty trucks, accumulators are commonly employed to improve the responsiveness and stability of hydraulic systems, ensuring consistent performance under varying load conditions 1.

Purpose of the 4307128 Accumulator

The 4307128 Accumulator is specifically designed to play a role in the hydraulic systems of commercial trucks by storing and releasing hydraulic fluid as needed. This function helps in maintaining system pressure, reducing shock loads, and enhancing the overall efficiency of hydraulic operations. By providing a reserve of pressurized fluid, it ensures that the hydraulic system can respond quickly to demands, thereby improving the truck’s operational performance 2.

Key Features

The 4307128 Accumulator features a robust design that includes high-quality materials to ensure durability and reliability. Its construction typically involves a metal housing and a bladder or piston to separate the hydraulic fluid from the gas charge. This design allows for efficient energy storage and release. Additionally, the accumulator may include safety features such as pressure relief valves to protect the system from over-pressurization 3.

Benefits of Using the 4307128 Accumulator

Utilizing the 4307128 Accumulator in a truck’s hydraulic system offers several advantages. It contributes to improved system efficiency by maintaining consistent pressure levels, which can lead to enhanced performance and reduced wear on system components. The accumulator also provides reliability in various operating conditions, ensuring that the hydraulic system operates smoothly even under demanding situations 4.

Installation and Integration

Proper installation of the 4307128 Accumulator is crucial for its effective operation within a truck’s hydraulic system. This process involves ensuring that the accumulator is correctly positioned and securely mounted. It may also require adjustments to the system’s plumbing to accommodate the accumulator. Careful attention to manufacturer guidelines during installation helps in achieving optimal performance and longevity of the component.

Troubleshooting Common Issues

Common issues with the 4307128 Accumulator may include leaks, inconsistent pressure levels, or failure to maintain system pressure. Troubleshooting these problems often involves inspecting the accumulator for signs of damage or wear, checking the system’s plumbing for leaks, and ensuring that the accumulator is properly charged. Addressing these issues promptly can help in maintaining the efficiency and reliability of the hydraulic system.

Maintenance Tips

Routine maintenance of the 4307128 Accumulator is important for ensuring its longevity and optimal performance. This includes regular inspections for signs of wear or damage, checking the system’s pressure levels, and ensuring that the accumulator is properly charged. Following manufacturer recommendations for maintenance intervals and procedures can help in preventing issues and ensuring consistent performance.

Safety Considerations

When working with the 4307128 Accumulator, it is important to observe safety guidelines to protect both the equipment and personnel. This includes ensuring that the system is depressurized before performing any maintenance or repairs, using appropriate personal protective equipment, and following manufacturer safety recommendations. Adhering to these precautions helps in maintaining a safe working environment.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence underscore its leadership in the power industry.

Cummins Engine Compatibility with Part 4307128

The Cummins part 4307128, an Accumulator, is designed to fit seamlessly within a range of Cummins engine models. This part is integral to the engine’s operation, ensuring smooth and efficient performance. Below is a detailed look at the compatibility of this accumulator with the specified engine models:

ISX15 CM2350 X101

The ISX15 CM2350 X101 engine is equipped with the 4307128 accumulator, which plays a role in maintaining the engine’s hydraulic system. This part ensures that the engine’s various components receive the necessary hydraulic pressure, contributing to the overall reliability and efficiency of the engine.

QSX15 CM2350 X105

Similarly, the QSX15 CM2350 X105 engine utilizes the 4307128 accumulator. This component is essential for the proper functioning of the engine’s hydraulic systems, ensuring that all parts operate smoothly and efficiently.

X15 CM2350 X116B and X15 CM2350 X123B

Both the X15 CM2350 X116B and X15 CM2350 X123B engines are compatible with the 4307128 accumulator. This part is designed to integrate seamlessly with these engines, providing the necessary hydraulic support to maintain optimal performance. The accumulator’s role in these engines is to ensure that the hydraulic systems function correctly, contributing to the engine’s overall reliability and efficiency.

X15 CM2450 X134B

The X15 CM2450 X134B engine also benefits from the 4307128 accumulator. This part is crucial for the engine’s hydraulic systems, ensuring that all components receive the necessary pressure to operate smoothly and efficiently. The accumulator’s integration into this engine model is designed to enhance performance and reliability.

By ensuring that the 4307128 accumulator is correctly installed and functioning, these Cummins engines can maintain their performance and longevity, providing reliable power for various applications.

Role of Part 4307128 Accumulator in Engine Systems

The 4307128 Accumulator is a component in the hydraulic systems of various engine setups, particularly those involving fuel injection systems. Its primary function is to store hydraulic pressure, ensuring a consistent and reliable supply of fuel to the injectors.

Interaction with Fuel Injectors

In fuel injection systems, the 4307128 Accumulator works in tandem with fuel injectors to maintain optimal performance. By storing pressurized fuel, it ensures that injectors receive a steady flow, which is vital for precise fuel delivery. This consistent pressure helps in achieving better atomization of the fuel, leading to more efficient combustion and improved engine performance.

Contribution to Plumbing Systems

The Accumulator is also integral to the plumbing systems within the engine. It acts as a buffer, smoothing out pressure fluctuations that can occur due to the dynamic nature of engine operations. This stabilization is particularly important in high-performance engines where even minor pressure variations can affect the overall efficiency and reliability of the system.

Enhancing Overall Performance

By ensuring a stable pressure supply, the 4307128 Accumulator contributes to the overall performance of the engine. It helps in reducing the wear and tear on other components by providing a consistent operating environment. This reliability is especially beneficial in high-stress scenarios, such as racing or heavy-duty applications, where engine components are subjected to extreme conditions.

Conclusion

In summary, the 4307128 Accumulator plays a role in maintaining the integrity and performance of engine systems by ensuring a stable and consistent pressure supply to critical components like fuel injectors and plumbing systems.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩

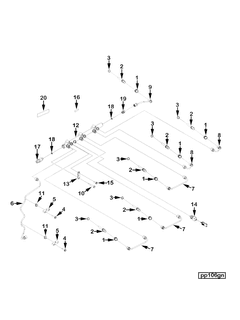

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.